All about Analog Layout Design

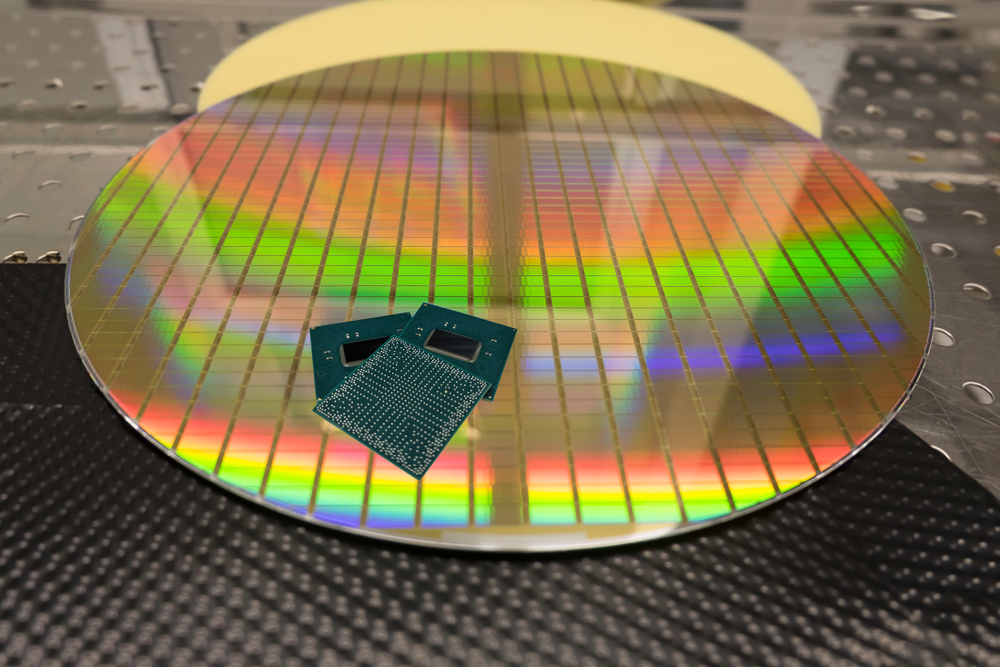

Analog layout design in the field of integrated circuit (IC) design is a discipline that deals with physical implementation of schematic blocks to the chip top level. The field of Analog Layout Design focuses on the chip layout design for a particular Analog and digital mixed-signal design. Candidates who take Analog Layout Design will be prepared for the following at the end of their course:

- Work in Linux environment

- Schematic entry in EDA tools

- Understanding of routing processes and physical verification checks like Layout versus Schematics (LVS) for classic Analog circuits (Bandgap, LDO, Opamp, PLL, and Standard cells.

- Understanding of Design Rule Checking (DRC)

- Dealing with deep sub-micron process matters like Lachup, Antenna, EM, and IR

- Tapeout

At Upgrade VLSI Technologies, our Analog Layout Training also covers the area of IO and Memory Layout Training. Therefore, when you sign up for your training with us, you will be well equipped to delve into different areas of Analog and Mixed-Signal layout design, Standard Cell Layout Design Memory Layout Design, and IO layout design.

How to Become an Analog Layout Engineer

To become an Analog Layout Engineer, you will be required to obtain at least a Diploma in ECE/EEE or a bachelor’s degree in Electrical Engineering and Technology. Companies will accept people with layout design training for entry-level employment as Analog Layout Engineers.

Areas Covered by Analog Layout Design

In-depth Knowledge of MOSFET (Metal Oxide Semiconductor Field Effect Transistor):

The MOSFET transistor is a semiconductor device that enables switching purposes and the amplification of electronic signals in electronic devices. There are two types of MOSFET, the P, and N-Channel MOSFET and Analog Layout Design Engineers need to have an in-depth understanding of how both channels work and how to incorporate them into the design.

MOSFET Amplifiers can serve a wide range of purposes, especially in frequency applications. They also serve in the production of DC regulation. It is also useful in the area of chopper amplifiers. MOSFET can be found in many electronic devices as a passive component.

Routing Process and Physical Verification Using Standard Checking Rules

Layout versus Schematics (LVS)

LVS is an essential verification process that analyses the physical verification stage. The LVS generates a layout netlist through the extraction of geometries. A comparison is then made between the layout netlist and the schematic netlist at every stage of the verification to ascertain whether they match functionally. If both netlists correspond which each other, then the LVS result is clean. In case of a mismatch error, the LVS tool identifies the location and the constituents of the mismatch. Some identifiable errors in LVS verification are:

- Shorts: identifies overlapping wires that are not supposed to be connected

- Opens: Incomplete connection for certain nets

- Parameter mismatch: identifies mismatches in parameter, i.e., if there is a difference in the value of a specific component in the schematic and the layout

Design Rule Check (DRC)

The DRC rule is essential in the verification of certain defined rules by the fabrication team. Some of these rules are:

- The number of spaces between metal layers

- The minimum width rule

- The via rules etc.

In other words, Design Rule Checks (DRC) is a physical design check to ensure that metal widths, spacing requirements, and pitch for the various metal layers will adhere to different fabrication methods. Without the DRC rules, a physical connection will lead to chip functionality failure. Therefore, it is essential to ensure a clean DRC report before giving a physical connection to fabrication.

Antenna Rule Checking (ARC)

Antenna rule checking ensures that the final design has no antenna effects.

Electrical Rule Checking (ERC)

Electrical Rule Checking ensures that the final design corresponds with all electrical requirements for the design.

Duties of an Analog Layout Design Engineer

In simple terms, Analog Layout Design Engineers are electrical engineers that design and develop the circuitry found in different Analog electronic devices we use today. They are responsible for creating and testing unique circuits for different devices to ensure that they work as expected.

They also work in collaboration with the manufacturing team to ensure that the process goes according to specification. The duty of the Analog Layout Design Engineer is tasking and the engineer may be required to work longer hours per week to meet the deadline.